Based on the scan results a schedule to rescan should be based on the types of equipment power consumption and age of the electrical systems.

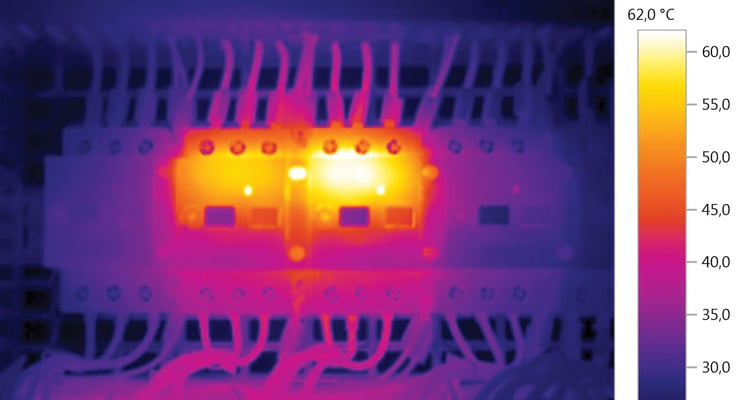

Thermography test for electrical panels.

Why is thermographic testing of electrical equipment important.

Infrared thermography is a test that can be utilised to identify unbalanced loads poor connections deteriorated insulation or any other issues in energized electrical panels or components without dismantling the components.

Thermographic test or electrical thermography or thermal imaging is the technique that uses an infrared imaging and measurement camera to see and measure invisible infrared energy being emitted from an object.

Thermography test of electrical panels.

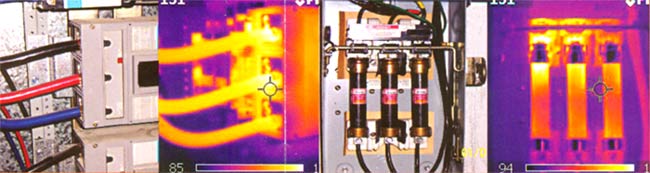

Thermographic test or thermography test services for your electrical panels and systems helps you to manage your electrical and fire safety risks.

These problems may lead to excess power use increased maintenance costs or.

Thermal imaging is the method utilised for detecting and visualizing the electrical faults.

Thermography is a method of inspecting electrical and mechanical equipment by obtaining heat distribution pictures this inspection method is based on the fact that most components in a system show an increase in temperature when malfunctioning.

This type of fault is easy to detect using infrared cameras.

The primary application for infrared thermography is electrical applications.

Businesses with high electrical demands should have a thermographic scan performed at least annually on critical systems such as circuit panels switchgears and transformers.