As noted in the chart below created from rs means data if you compare the life cycle costs of a sarnafil roof estimated to last 35 years versus a tpo roof lasting 20 years pvc is the less expensive choice.

Thermoplastic pvc tpo roof membrane.

In addition to being energy star rated tpo s recyclability makes it an environmentally conscious system.

Tpo in a nutshell a tpo membrane is made from ethylene propylene rubber.

This membrane is best recognized for having the benefits of epdm and pvc systems at a more economical cost.

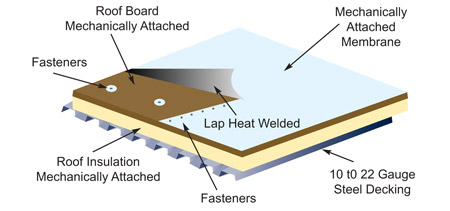

Thermoplastic membranes such as pvc or tpo are generally sealed by heat welding with hot air or by using solvents to weld the sheets together.

Pvc s are documented to last longer than tpo membranes who are still experiencing premature failures.

Tpo is a type of membrane roofing suitable for flat and low slope roofs.

Carlisle s sure weld tpo membranes have the industry leading octaguard xt weathering package for enhanced long term weathering.

Tpo membranes are white and highly reflective making them an excellent choice for those looking to reduce energy costs.

Sikaplan is a cost competitive single ply pvc roofing membrane designed for low slope roofing applications.

Tpo membranes are made with a co polymerized rubber that allows them greater flexibility in cold climates.

Roofing calculator in the building trades the acronym tpo stands for thermoplastic polyolefin a material originally developed for pond liners and used extensively for roofing since 1989.

The most common thermoplastic roof membranes are pvc and tpo.

Tpo thermoplastic polyolefin membrane is the largest segment in the commercial roofing industry and no manufacturer has more tpo experience than carlisle.

It s therefore not surprising that tpo roofing systems are quickly growing in popularity and demand in both residential and commercial flat roof markets.

Unlike sarnafil which is formulated to perform above and beyond the industry standard sikaplan is formulated to the industry standard like the rest of the thermoplastic roofing membranes on the market.

Thermoset membrane roofingis fully cured during manufacture so it cannot be bonded to an adjacent sheet with heat or solvents.

Polyvinyl chloride pvc pvc sheets are produced by calendaring spread coating or extruding and typically are reinforced with polyester or glass fiber mats or scrim.